Wheel Offset vs. Backspacing

Offset and backspacing are two commonly used terms in wheel measurement but can be confusing at times. While the terms are related, many people will ask what is the best, or most, backspacing I can use to fit a particular wheel/tire combination. Unfortunately, most wheel manufacturers use offset for a measurement and not backspacing. Let's try to clear up this often misunderstood terminology and learn how to measure offset and the resulting backspacing.

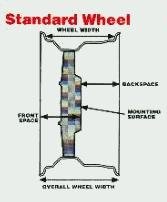

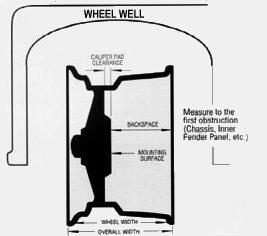

Advertised wheel width is generally measured at the inside tire bead mounting surface but you must determine the overall wheel width from the front to rear lip - usually 1-inch total. So a wheel that is advertised as 16x8 is 16-inches in diameter, 8-inches from tire bead to tire bead but 9-inches wide overall.

0-inch offset ~ Backspacing determined by wheel width

Offset ~ The distance from the mounting pad to the centerline of the wheel. Offset can be positive (more backspacing) or negative (less backspacing).

Backspacing ~ The measurement from the mounting pad to the inner edge of the wheel.

(These are definitions supplied by ARE. Other wheel manufacturers may use different points of measurement.)

Let's assume you have a 17x8-inch wheel. Lay the wheel on the ground with the front (street side) facing down. Lay a straight edge across the rear (top) lip and measure from this lip to the mounting flange. If the wheel has "zero" offset, this will measure about 4.5 inches - one half the width of the wheel plus the wheel lip width (approx. 0.5") and result in a 4.5-inch backspace. (Again, ARE measures differently. A 17x8 ARE 200S with zero offset has 4.5" of backspacing to the inner edge of the wheel and not to the bead.)

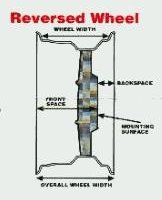

Negative Offset (less backspacing)

If you remember the days of the 'deep-dish' or chrome-reverse wheels, you've seen negative offset. The mounting flange of the wheel is moved from the centerline towards the car itself resulting in the wheel having a greater lip surface towards the outside. Not only does this reduce the clearance between the tire and the wheel well lip for your tires, it puts more strain on the wheel and axle bearings.

Negative offset = less backspacing

The American Racing Outlaw I model wheel is a good example of a wheel with negative offset. In a 15x8 size this wheel is listed as having -19mm offset resulting in 3.75-inches of backspacing. Let's see how this is arrived at.

* 8-inch wheel is 9-inches from lip to lip.

* One-half of 9-inches is 4.5-inches.

* -19mm offset is roughly -0.75-inches.

* Add the -0.75-inches offset to the mounting surface location of 4.5-inches

and you get 3.75-inches of 'backspacing'

Positive Offset (more backspacing)

Positive offset can be seen on many of today's modern cars with front wheel drive. The centerline of the wheel is moved towards the front (street side) resulting in more backspacing. With disc brakes and wider tires being standard equipment, the positive offset allows the wheel/tire combination to fit inside the wheel well instead of protruding past the fender lip. This wheel has a positive offset of over 40mm thereby moving the mounting flange over 1.5-inches toward the street side of the wheel.

Positive offset = more backspacing

The American Racing Split model wheel is a good example of a wheel with positive offset. In a 15X7 size this wheel is listed as having +40mm offset resulting in 5.5-inches of backspacing. Let's see how this is arrived at.

* 7-inch wheel is 8-inches from lip to lip.

* One-half of 8-inches is 4-inches.

* +40mm offset is roughly 1.575-inches.

* Add the 1.575-inches offset to the mounting surface location of 4-inches

and you get 5.575-inches of 'backspacing'

These terms can be confusing at times as some manufacturer's list the backspacing, some list offset, and some list both. Just remember that backspacing is a direct result (or byproduct) of offset.

Many wheel manufacturers also list backspacing or offset in millimeters instead of inches, so a little math conversion comes into play here.

For the Chevelle owner with a 5 lug, 4.75-inch bolt circle wheel pattern, two 17x8 models of the ARE 200S wheel are offered; one with +14mm offset and one with -12mm offset. I use this wheel as an example only because I had a set of these and, personally, I prefer ARE wheels. Be sure to check with your choice of wheel companies to see how their offset/backspacing is measured.

First we must learn to deal with the metric measurements and convert those to inches. Multiply the metric measurement by 0.03937 to get the measurement in inches. For example: +14mm is equivalent to 0.55 inches. The +14mm is a positive offset of 0.55 inches so that will move the mounting flange 0.55 inches closer to the front of the wheel resulting in a 5.05-inch backspacing - much like the OFFSET picture at the top of the page. The other wheel has a -12mm offset (negative) that calculates to 0.4724 inches.

The negative offset will move the mounting flange closer to the back of the wheel resulting in less backspacing; 4.0276 inches (4.50 - .4724) in this case. Negative offset gives the wheel that "deep dish" look but can play havoc with the wheel well and front wheel bearings.

The published figures by ARE for this wheel are:

17x8 w/+14mm offset ~ 5" backspacing

17x8 w/-12mm offset ~ 4" backspacing

The American Racing wheel website has some very good technical articles explaining offset, backspacing, how to measure, how to decide on the correct wheel. Visit them at http://www.americanracing.com and click the TECH CENTER link.

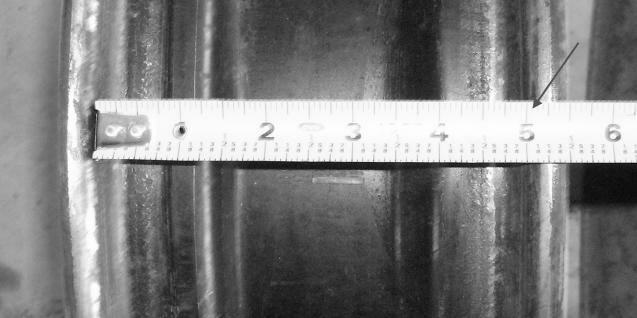

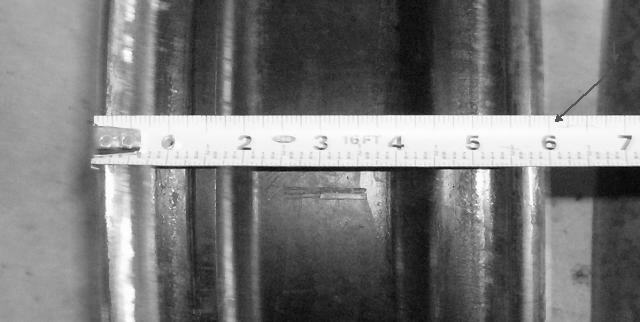

Here's a practical example using a basic Chevrolet 14x5-inch steel wheel.

The advertised width, 5-inches, is measured from bead-to-bead, not from the outer edges of the rim. The same wheel measures 6-inches from outside edge-to-outside edge. Knowing this outside width is important for a couple of reasons. First, to measure the backspace, (or offset), this outer edge is used as a reference point. Second, when the wheel and tire are installed on the car, this extra 1-inch plus must be taken into account for clearance.

Laying the wheel (without a tire) face down on a level surface, lay a straight edge across the back side of the wheel. Measure from the wheel-to-drum/disc mounting pad to the straight edge. In this example, the measurement is 4-inches.

To calculate backspacing or offset, you take the overall wheel width of 6-inches (from edge-to-edge) and divide that by 2 to find the centerline of the wheel. In this case, half of 6-inches is 3-inches. The backspacing is the 4-inches shown in the photo above. That 4-inch backspacing results in 1-inch offset from the centerline of the wheel. Since the offset is towards the outside of the wheel, moving the wheel/tire closer to the suspension, this offset is considered to be a positive offset.

If the 4-inches shown above were instead, say 2-inches, the backspacing would be that 2-inches and the offset would still be 1-inch but it would be a negative offset putting the wheel/tire combination closer to the wheel well edge and away from the suspension. In days gone by this negative offset was called a 'reversed' wheel or 'deep dish' design.