Build Sheet Myths/Facts

First off, the term "build sheet" or "build sheet" (choose your spelling preference) refers to the paperwork the assembly plant would produce to show the various substations of the plant what parts were to be used to build a particular car. This paperwork varies throughout the 1964-1972 model production years and different plants used different forms of paperwork. This paperwork was "broadcast" (sent to) the various substations so they could quickly pull the correct parts for their part of the assembly. The term "build sheet" is applicable to several types of this paperwork such as the BODY and CHASSIS BROADCAST COPY sheets typically used in non-General Motors Assembly Division (GMAD) plants before 1970.

In the case of the BODY and CHASSIS BROADCAST COPY sheets, the Fisher Body side of the assembly plant would get the BODY BROADCAST COPY sheet (example here) and the final assembly side of the assembly plant would get the CHASSIS BROADCAST COPY (example here). The BODY BROADCAST COPY sheet was often attached to the driver side firewall area when mated with the chassis and front sheet metal and have been found by owners when they remove the fenders. Often dealers would request a clean copy of the paperwork be sent with the car and the dealers would keep those on file.

From 1964 through 1967 the trim shop may use their own trim sheet to direct them with the interior trim selection. The trim sheet would have an internal sequence number, the date the information was "broadcast" to them, an internal job number, the car's color and body number along with various codes to depict options that would require changes from a base car.

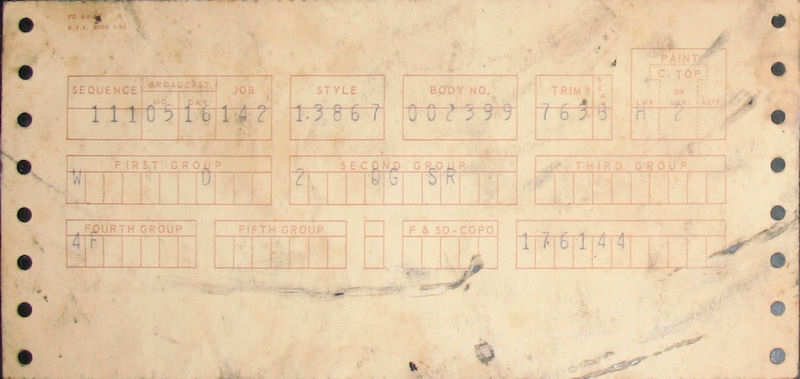

This is NOT a build sheet but rather an Interior Trim Sheet found in

many pre-1969 Chevelles. Some data can be gleaned from these though.

The BROADCAST MO. & DAY of 05 16 is May 16 The STYLE of 13867 is an

SS396 convertible. BODY NUMBER of 002399 is assigned by Fisher Body

and is unique to SS396 convertibles; meaning (for example) an SS396

sport coupe built the same day would have a body number correlating

to the SS396 sport coupe(1).. TRIM of 763B is black

bucket seats and PAINT COLOR "H" AND "2" are lower and upper paint

codes for Willow Green (H) and a black convertible top (2). The

second line are options ordered that will cause the Fisher Body side

of the plant to modify a base car.

The SEQUENCE, JOB, and the 6-digit number in the lower right are

all internal Fisher Body numbers but the JOB number does appear on

Baltimore trim tags; however, Baltimore did NOT include the group

option codes on their tags.

FIRST GROUP

W is RPO A01 for tinted windshield

D is RPO C06 for power convertible top

SECOND GROUP

2 - to note group 2

Q is RPO M21 for a close ratio 4-speed transmission

G is RPO D55 for a center console

S is RPO U73 for a rear mounted antenna

R is RPO U80 for a rear speaker

FOURTH GROUP

4 - to note group 4

F is RPO Z19 for Comfort and Convenience group

Note there are no THIRD GROUP or FIFTH GROUP options.

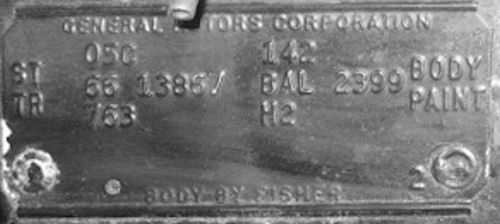

This is the Fisher Body Number Plate for the SS396 convertible

above. Note the only Fisher Body internal number noted on the

trim tag is the JOB number, 142.

(1) From 1964 through 1968 Fisher Body would assign

(generally sequential) body numbers based on the STYLE. For example,

an 05C dated Malibu sport coupe would have a significantly higher

body number such as 15583 than the SS396 convertible's 2399 simply

because more Malibu sport coupes had been built to that point in

time.

This was often attached to the seat and sent on its way to its assembly point and are often found in 1964-1967 model year Chevelles.

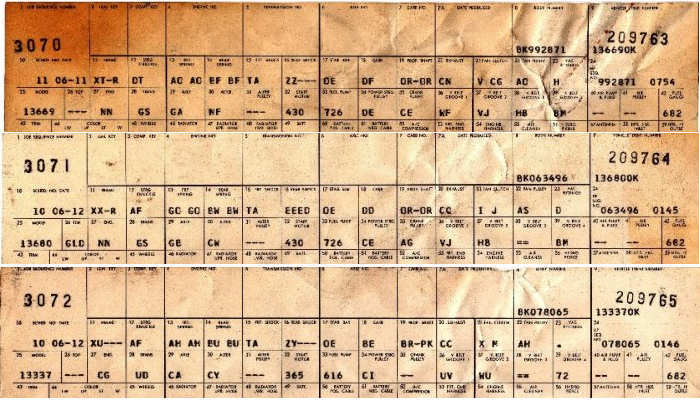

The "build sheet" terminology is frequently used to describe the variations of broadcast copy sheets. Prior to the 1969 model year only the Fremont, CA. and Framingham, MA. assembly plants used this form of paperwork. This example is a 1967 Custom El Camino broadcast copy sheet from the Fremont, CA. assembly plant. In 1969 the Fisher Body/Chevrolet separation was merged into one organization, the General Motors Assembly Division and plants began to "standardize" on their broadcast assembly paperwork. Although the overall format of the infamous "build sheet" changed over the ensuing years and data were depicted with plant-specific verbiage and use of various blank (unlabeled) boxes, the "build sheet" has become the holy grail of documentation for SS optioned Chevelles.

Second, this paperwork was not 'hidden' in your car for you to discover 10, 20, 30, or more years later like a treasure hunt. Once a workstation was done with their particular operation on the car the paperwork was useless to them. Various assembly substations would get their own copies of the "build sheet" and may or may not have attached their copy to the assembly they worked on; maybe to identify the car the assembly was going to be installed on and/or maybe just to get rid of the paperwork from their work area. Employees at the various assembly plants did not get together and decide to hide this paperwork so you could find it many years later and there was no standard operating procedure to attach the paperwork to any specific area of the car. There are some more common locations the paperwork have been found; the trim shop at Atlanta in 1970 tended to glue a copy of the paperwork to the inside passenger door card, Arlington would often leave a copy under the driver side footwell, Van Nuys is known for leaving a copy on top of the gas tank. See here for examples for these locations.

If any paperwork was visible during the car's final inspection it would be pulled and trashed along with anything else that a worker may have left in the car like tools, soft drink cans, candy wrappers, etc. Dealers would often request a copy of the paperwork be shipped with each car they ordered from a factory and many dealer's old files still have this paperwork and is found (along with order forms, contracts of the sale, car shippers, dealer invoices, etc.)

Often a build sheet (and sometimes multiple build sheets) are found in Chevelles that do not belong to that particular car. One Kansas City-built Chevelle owner found three build sheets in his car and all three were sequential builds but not one of those three were his car. Another Chevelle owner of a Kansas City-built Chevelle found his build sheet along with the build sheet of a Buick Skylark in this car. Cases like these would indicate that often a workstation would simply toss any paperwork they had left into a Chevelle just to get rid of it from their workstation. Interesting to note that sequence number 209763 was the last Chevelle scheduled for June 11 (06-11) and 209764 was the first Chevelle of the day for June 12 (06-12). An oddity on these sheets is the first 2-digit number, the SCHED number. Normally for the Kansas City plant's SCHED number is the physical workday for a given month. But the first sheet shows a SCHED day of 11 with an 06-11 date. June 11 would have been the 9th working day of the month. The second two have a SCHED number of 10 and a NO DATE of 06-12 or June 12. June 12 would have been the 10th workday of June 1970. Unfortunately no other 06-11 or 06-12 dated sheets have come to light so far to try and understand why the discrepancies of these three.

Say you saw it here on © ChevelleWorld

Want more in-depth information on 1964-1972 Chevelles? My 1970 SS 396/SS454

Build Sheet Decode Program CD, Shop Manuals & Parts Catalog program DVD, Facts and SS

Guide program CD, 1964-1972 Trim Tag and Protect-O-Plate program CD,

and my Chevy Numbers program CD. Check

them and other informative program CDs at my

https://chevellecd.net website.

1964 Chevelle

1964 Chevelle 1965 Chevelle

1965 Chevelle 1966 Chevelle

1966 Chevelle 1967 Chevelle

1967 Chevelle 1968 Chevelle

1968 Chevelle 1969 Chevelle

1969 Chevelle 1970 Chevelle

1970 Chevelle 1971 Chevelle

1971 Chevelle 1972 Chevelle

1972 Chevelle