Emission Systems - Evaporation Control System (ECS) 1970 and later

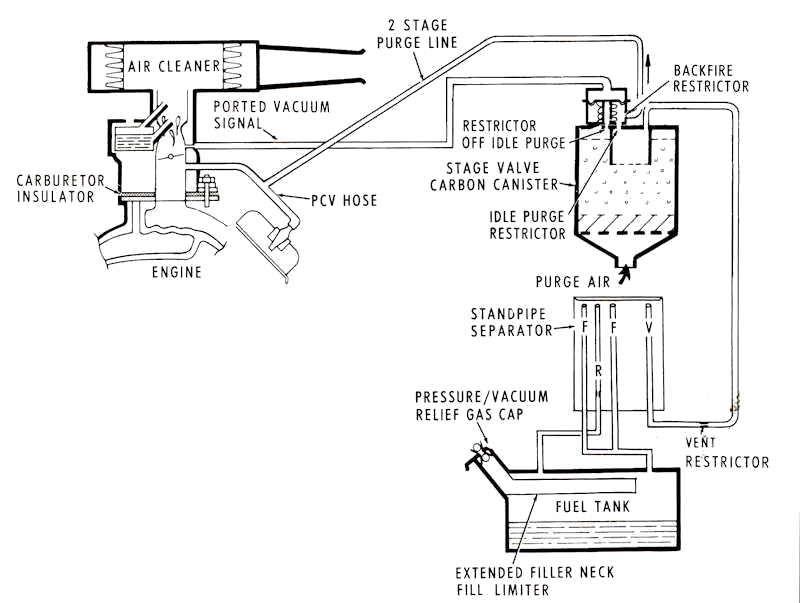

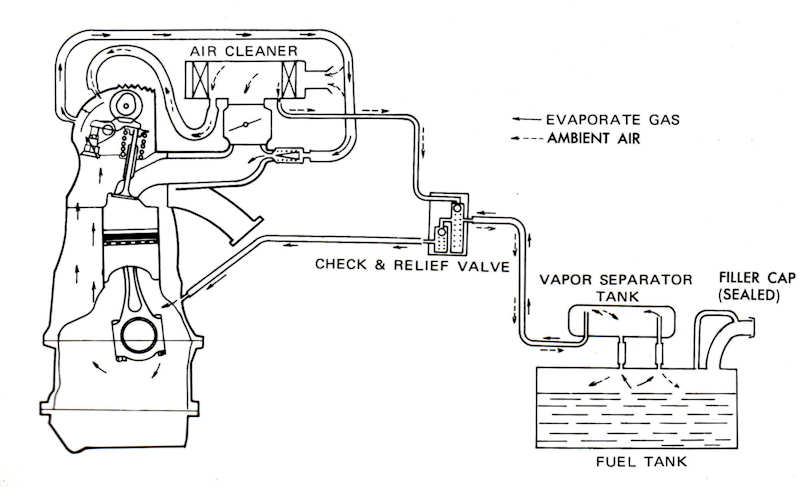

Evaporation Control System (ECS) is designed to minimize the loss of vaporized gasoline to the atmosphere.

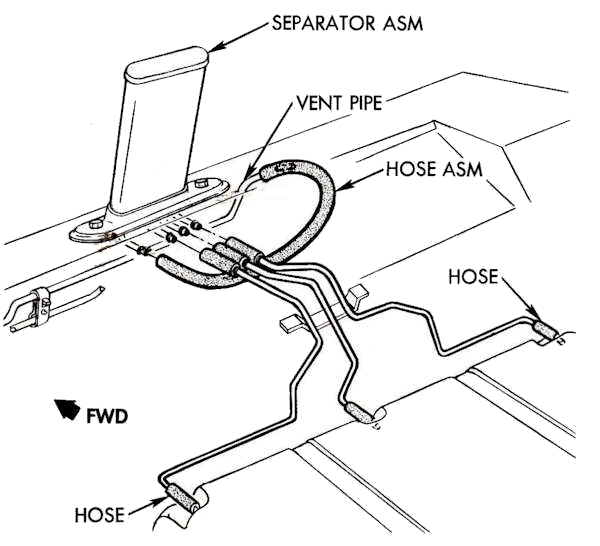

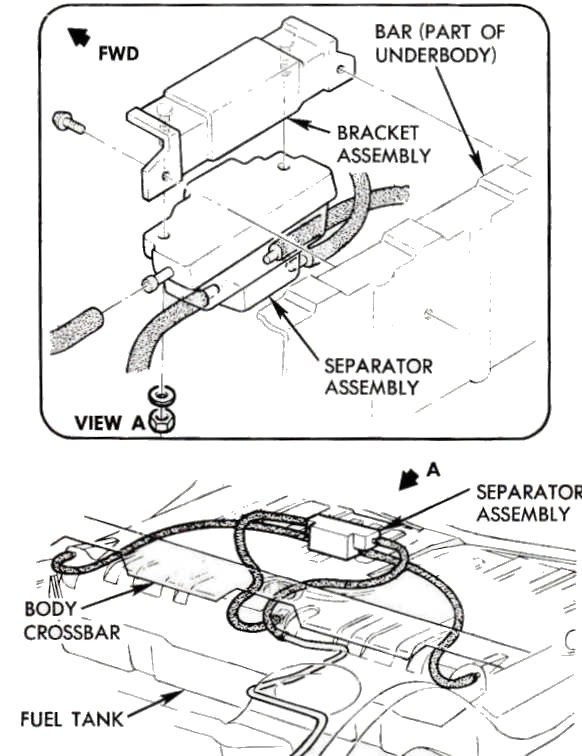

The system is composed of a fuel tank separator, vapor lines, and a storage container.

As vapor forms in the fuel tank, it passes through the liquid/vapor separator. The function of the liquid/vapor separator is to return liquid fuel tot he fuel tank and allow only vapor to enter the storage canister. Liquid fuel accumulates in the separator from vehicle maneuvering, parking on steep grades or from condensed vapor. From the vapor lines it enters the activated charcoal canister. When the engine is started, air is drawn through the bottom of the canister to extract the vapors from the charcoal and induct them via the carburetor where they become part of the fuel mixture and are burned in the combustion process.

The Chevrolet LUV ECS does not use a carbon canister to store the fuel vapors. Instead of the canister, fuel vapors are stored in the crankcase through the use of a combination check and relief valve. Here the vapor mixes with blow-by gases and are drawn, along with filtered air from the carburetor air cleaner, into the intake manifold via the crankcase ventilation system. In order to prevent vapor flow into the air cleaner, the relief valve at the air cleaner side of the check and relief valve remains closed while the check valve to the crankcase is open.

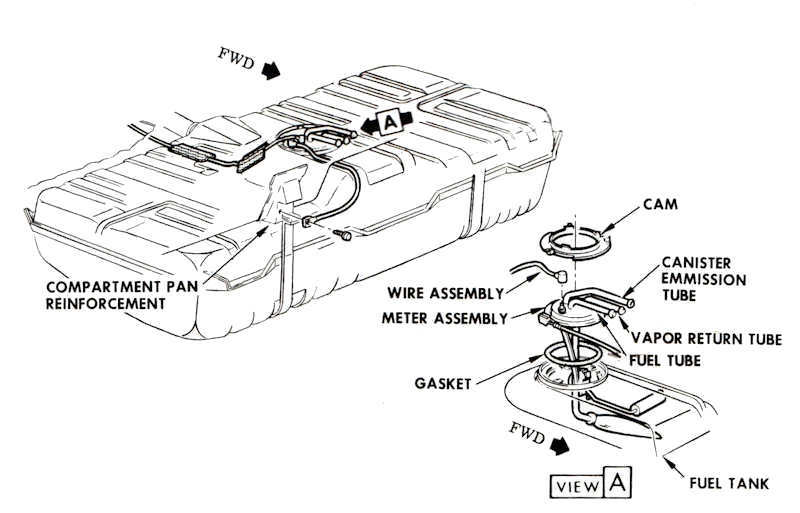

In 1973, the ECS liquid vapor separator was replaced with a dome type fuel tank and redesigned fuel tank meter unit on all vehicles except the Camaro and Corvette. The new fuel tank and meter unit perform the same function as the vapor separator. The domed portion of the fuel tank provides a collection and separation chamber for the rising vapors, while the fuel meter incorporates the vapor feel tube to the canister in addition to the fuel supply tube.

Vapor canister on a 1970 Chevelle built at the Van Nuys, California

assembly plant.

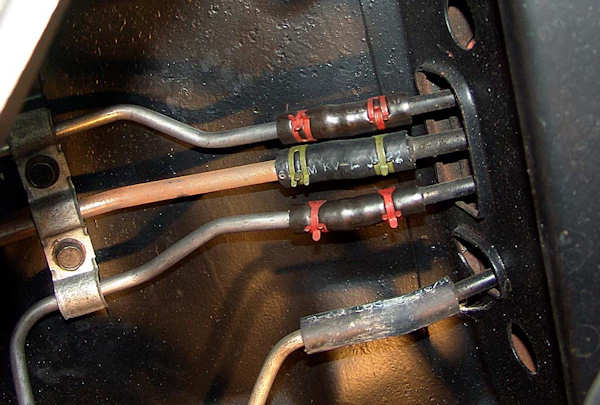

Ball check separator.

FUEL TANK

In order to collect as much vapor as possible, the fuel level was reduced by lowering the filler neck from the highest point of the tank by about one inch. Fuel venting occurs at three positions on the tank; the left front, center, and right front. This allows for at least one of the three to be open during normal operation. These vents allow fuel and fuel vapor to flow from the top of the fuel tank to the liquid/vapor separator.

LIQUID/VAPOR SEPARATOR - 1971/1972

|

Pressure in the separator allows the vapor to leave the separator and enter thru routing lines to the charcoal canister. Any liquid that accumulates in the separator is returned to the fuel tank via the center vent pipe. One type is the standpipe separator shown here. |

|

| A second type of liquid/vapor separator is the ball check separator. |

|

© ChevelleWorld

1964 Chevelle

1964 Chevelle 1965 Chevelle

1965 Chevelle 1966 Chevelle

1966 Chevelle 1967 Chevelle

1967 Chevelle 1968 Chevelle

1968 Chevelle 1969 Chevelle

1969 Chevelle 1970 Chevelle

1970 Chevelle 1971 Chevelle

1971 Chevelle 1972 Chevelle

1972 Chevelle