Engine Assembly Order

The following assembly for Flint and Tonawanda engine plants is general in nature as small variations were usually made from year to year.

| Flint | Tonawanda |

| Raw castings enter plant | Raw castings received from other parts of Tonawanda engine plant |

| Block machining (broaching) in 1 to 2 days | Block washed |

| Block begins upside down. Bore sizes on oil pan rail broadcast ahead to piston hook up area. | Oil galley plugs |

| Galley plugs | Transmission alignment pins |

| Camshaft | Camshaft |

| Main bearing caps removed, crank installed, caps reinstalled. | Main bearing caps removed, crank installed, caps reinstalled. |

| Flywheel & pressure plate | Flywheel & pressure plate |

| Cam & crankshaft gears, timing chain | Cam & crankshaft gears, timing chain |

| Piston installation | Piston installation |

| Front engine cover and seal | Front engine cover and seal |

| Harmonic balancer | Harmonic balancer |

| Oil pump shaft and oil pump | Oil pump shaft and oil pump |

| Windage tray bolts if applicable | Windage tray bolts if applicable |

| Oil pan and hardware | Oil pan and hardware |

| Clutch housing | TDC determined, timing pointer |

| Engine turned upright | Engine turned upright |

| TDC determined, timing pointer | Cam & lifters |

| Cam & lifters | Build date/suffix code stamped |

| Cylinder heads installed | Cylinder heads installed |

| Rocker arms studs, arms, & balls installed | Rocker arms & balls installed (studs already installed) |

| Intake manifold installed | Valves adjusted |

| Valves adjusted | Intake manifold installed |

| Valve covers installed | Water outlet & thermostat installed |

| Miscellaneous brackets and switches installed | Water pump installed |

| Build date/suffix code stamped | Spark plugs installed |

| Water test with vacuum gauge | Distributor installed |

| Oil cavity test | Miscellaneous brackets installed |

| Paint assembly | Exhaust manifolds |

| Distributor installed | Vacuum test |

| Coil & plug wires | Valve covers |

| Spark plugs | Paint assembly |

| Temperature switches | Hot test |

| Water and oil drained | Water and oil drained |

| Exhaust manifolds installed | Racked & readied for shipment |

| Spark plug wire supports, heat shields, other miscellaneous brackets installed. | |

| Component verification | |

| Racked & readied for shipment |

Typically 396 engines were stamped on the left side (as facing the engine from the front of the car) before the heads were installed and will often be stamped under the cooling plug in the cylinder head. Small block engines were typically stamped on the right side (as facing the engine from the front of the car) of the engine pad.

Many people put faith in an original engine due to 'broach' marks on the engine pad but these marks were often either not present or very light.

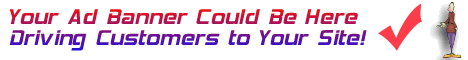

Two broach cutters are shown in this photograph. The cutter on the left broaches the pan rail and the upper half of the main bearing bores. The block is flipped over, registered and clamped on the pan rail, and the one on the right broaches the deck surfaces and the top horizontal surface between the decks. Each lateral row of cutting blades in each broach is set about .001" deeper than the row ahead of it. The block is clamped solid on its pallet and the overhead broach has about a six-foot stroke longitudinally across the block surface; one pass for the pan rail and one pass for the decks and top and it's done. Fresh blades in the tool left hardly any broach marks at all; as the blades wore, the broach marks became more visible.

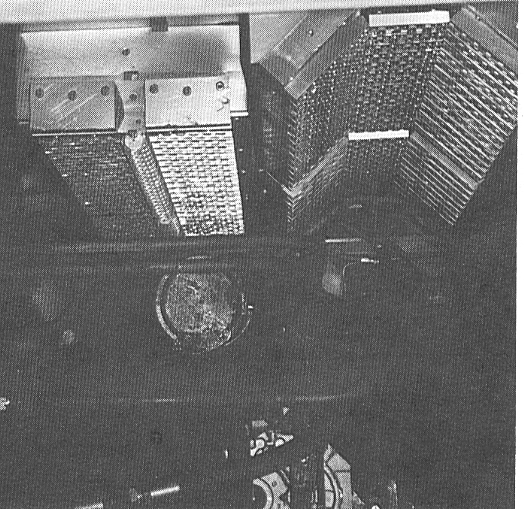

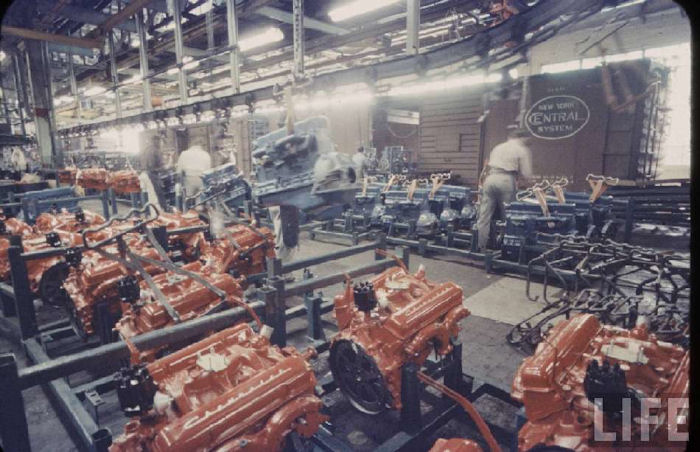

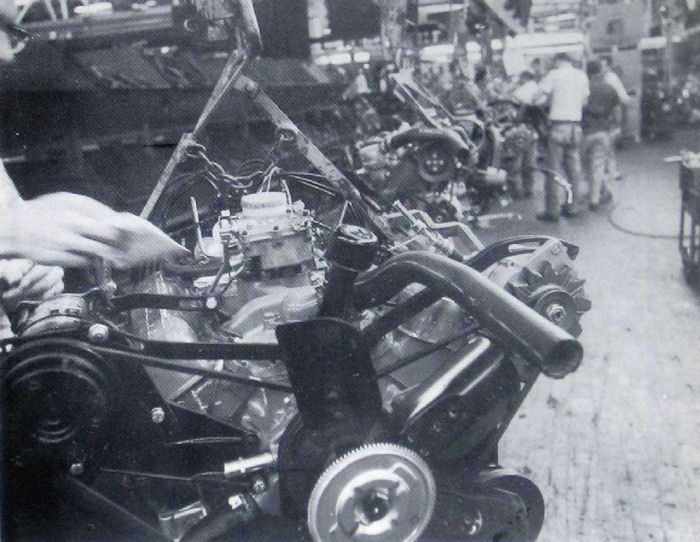

Engine blocks were shipped with distributor, exhaust manifolds and either a flywheel for manual transmission cars or a flex plate for automatic transmission cars. Although the photo below is from the mid-50s, the process of receiving engines, literally by the trainload, was still being used as the most economical method of shipping them. Engine assembly dates and suffix codes were already stamped on the engine pad.

Engine 'accessories' such as specific carburetor, belts/pulleys, alternators, starters, etc. were installed at the final assembly plant for the specific car. The partial VIN would be stamped when a specific engine was identified for a specific Camaro.

© GEN 2 CAMAROWORLD 1970-1973

1970

1970 1971

1971 1972

1972 1973

1973