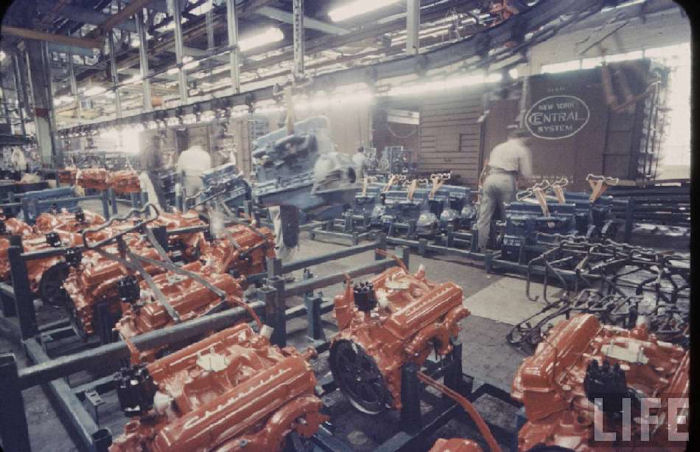

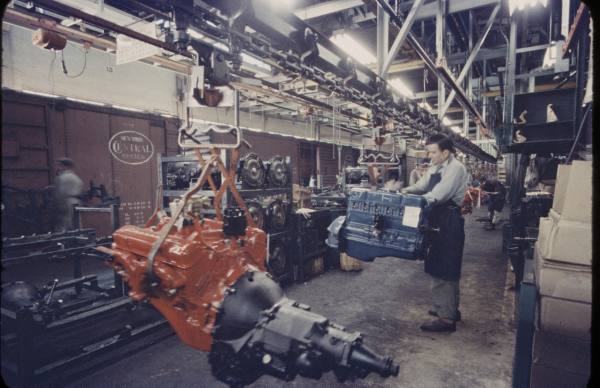

The following assembly for Flint and Tonawanda engine

plants is general in nature as small variations were usually

made from year to year.

| Flint |

Tonawanda |

| Raw castings

enter plant |

Raw castings

received from other parts of Tonawanda engine plant |

| Block machining

(boring/broaching) in 1 to 2 days and washed |

Block machining

(boring/broaching) and washed |

| Block begins

upside down. Bore sizes on oil pan rail broadcast

ahead to piston hook up area. |

Oil galley plugs |

| Galley plugs |

Transmission

alignment pins |

| Camshaft |

Camshaft |

| Main bearing

caps removed, crank installed, caps reinstalled. |

Main bearing

caps removed, crank installed, caps reinstalled. |

| Flywheel &

pressure plate or flex plate |

Flywheel &

pressure plate or flex plate |

| Cam & crankshaft

gears, timing chain |

Cam & crankshaft

gears, timing chain |

| Piston installation |

Piston installation |

| Front engine

cover and seal |

Front engine

cover and seal |

| Harmonic balancer |

Harmonic balancer |

| Oil pump shaft

and oil pump |

Oil pump shaft

and oil pump |

| Windage tray

bolts if applicable |

Windage tray

bolts if applicable |

| Oil pan and

hardware |

Oil pan and

hardware |

| Clutch housing |

TDC determined,

timing pointer |

| Engine turned

upright |

Engine turned

upright |

| TDC determined,

timing pointer |

Camshaft

lifters |

| Camshaft lifters |

Build date/suffix

code stamped * |

| Cylinder heads

installed |

Cylinder heads

installed |

| Rocker arms &

balls installed |

Rocker arms &

balls installed (studs already installed) |

| Intake manifold

installed (oil filler tube if applicable, water

outlet & thermostat already affixed) |

Valves adjusted |

| Valves adjusted |

Intake manifold

installed |

| Valve covers

installed |

Water outlet &

thermostat installed |

| Miscellaneous

brackets and switches installed |

Water pump installed |

| Build date/suffix

code stamped |

Spark plugs

installed |

| Water test with

vacuum gauge |

Distributor

installed |

| Oil cavity test |

Miscellaneous

brackets installed |

| Paint assembly |

Exhaust manifolds |

| Distributor

installed |

Vacuum test |

| Coil & plug

wires |

Valve covers |

| Spark plugs |

Paint assembly |

| Temperature

switches |

Hot test |

| Water and oil

drained |

Water and oil

drained |

| Exhaust manifolds

installed |

Racked &

readied for shipment |

| Spark plug wire

supports, heat shields, other miscellaneous brackets

installed |

|

| Component verification |

|

| Racked &

readied for shipment |

|

* Early (1965) 396-cid big block engines were stamped

further to the right on the engine pad due to the large

plug in the end of the cylinder head after assembly at Tonawanda.

This caused problems for the final assembly plants in stamping

the partial VIN identification. Later the engine ID information

was stamped on the left of the pad before the heads were

installed allowing the right side of the engine pad to be

used for the car's partial VIN to be stamped.