1967 SS 396

1967 SS 396 Engine Codes

|

Engine |

Transmission |

Notes |

||

| Code | Size-Carb | HP-RPO | ||

| ED | 396-4 | 325-L35 | Manual-3/4 | |

| EF | 396-4 | 350-L34 | Manual-3/4 | Heavy Duty Clutch |

| EG | 396-4 | 375-L78 | Manual-3/4 | Holley Carb/Solid Cam |

| EH | 396-4 | 325-L35 | Manual-3/4 | A.I.R./Rochester Carb |

| EJ | 396-4 | 350-L34 | Manual-3/4 | Heavy Duty Clutch/A.I.R. |

| EK | 396-4 | 325-L35 | Powerglide | |

| EL | 396-4 | 350-L34 | Powerglide | |

| EM | 396-4 | 325-L35 | Powerglide | A.I.R. |

| EN | 396-4 | 350-L34 | Powerglide | A.I.R. |

| ET | 396-4 | 325-L35 | TH-400 | |

| EU | 396-4 | 350-L34 | TH-400 | |

| EV | 396-4 | 325-L35 | TH-400 | A.I.R. |

| EW | 396-4 | 350-L34 | TH-400 | A.I.R. |

| EX | 396-4 | 375-L78 | Manual-3/4 | Holley Carb/Solid Cam/A.I.R. |

The 396 8-cyl engine was only available in the 13817/67 SS 396 series and both the 13480 and 13680 El Camino. The L35 396 cid 8-cyl engine was the base, or standard, engine in the SS 396. GM reports 1,865 L35 engines ordered as options and these would have been installed in the El Camino series.

1967 396 V8 Engine Production

The base engine for the SS 396 series for 1967 was the L35 396 cid 325-hp engine. This engine (along with the L34 and L78) was also an optional engine in the El Camino and 2,565 L35 engines were sold in the El Camino body style. There were a total of 63,006 SS 396s, sport coupes (59,685) and convertibles (3,321), sold. There is no way to know how many of the base L35 engines were sold in SS 396 sport coupes and/or convertibles. One can only take the number of L35 options known to be sold in the El Camino body style (12,565) and subtract that from the total number reported by Tonawanda and arrive at a number that would include Total L35 SS 396 Chevelles and Service Engines.

One cannot take the number of L34 or L78 engines into account for SS396 sales only since these were also available in the El Camino and only a total number of L34 and L78 options are known; what body style they went into is not known. Since it cannot be determined how many L35 engines were sold in the base SS396 series (Total L35 Engines) and the number of L35 service engines cannot be determined.

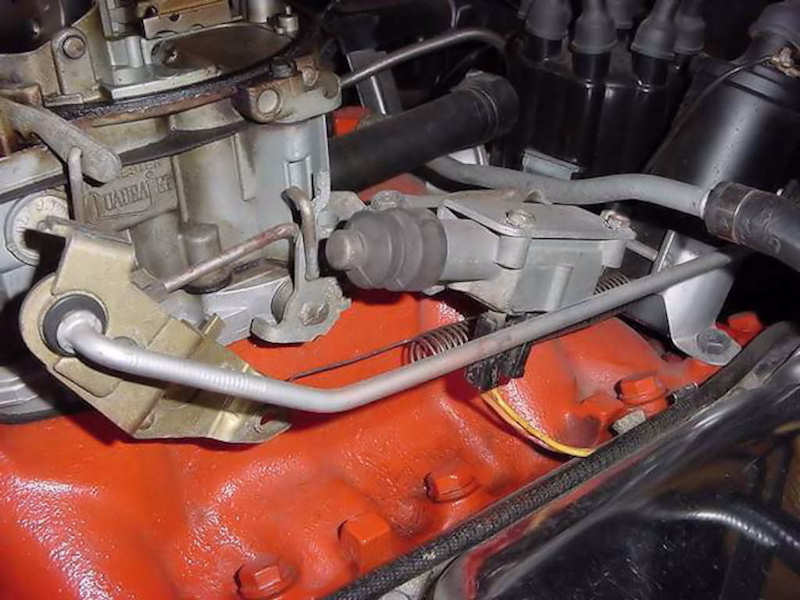

L35 engines are equipped with a Rochester (or Carter equivalent) Quadrajet carburetor; all L34 and L78 engines were equipped with a Holley carburetor.

| RPO | HP | Transmission | Suffix | Production | Notes |

| L35 | 325 | Manual | ED | 17,080 | |

| L35/K19 | 325 | Manual | EH | 04,172 | A.I.R. |

| L35/M35 | 325 | Powerglide | EK | 05,666 | |

| L35/K19/M35 | 325 | Powerglide | EM | 00,892 | A.I.R. |

| L35/M40 | 325 | TH-400 | ET | 09,166 | |

| L35/K19/M40 | 325 | TH-400 | EV | 02,725 | A.I.R. |

| 49,701 | Total L35 Engines | ||||

| 47,783 * | Total L35 Chevelles | ||||

| See paragraph above concerning service engines. | 01,918 | Service Engines | |||

| L34 | 350 | Manual | EF | 13,914 | |

| L34/K19 | 350 | Manual | EJ | 02,176 | A.I.R. |

| L34/M35 | 350 | Powerglide | EL | 00,160 | |

| L34/K19/M35 | 350 | Powerglide | EN | 00,018 | A.I.R. |

| L34/M40 | 350 | TH-400 | EU | 01,784 | |

| L34/K19/M40 | 350 | TH-400 | EQ | 00,346 | A.I.R. |

| 18,398 | Total L34 Engines | ||||

| 17,176 | Total L34 Chevelles | ||||

| 96.1% of total L34 engine production went into Chevelles in 1966. | 01,222 | Service Engines | |||

| L78 | 375 | Manual | EG | 596 | |

| L78/K19 | 375 | Manual | EX | 034 | A.I.R. |

| 630 | Total L78 Engines | ||||

| 312 | Total L78 Chevelles | ||||

| 018 | Service Engines | ||||

| 97.1% of total L78 engine production went into

Chevelles in 1967 * It is known that 12,565 of these L35 engines were sold as options in the two El Camino series. |

|||||

The base 325-hp

L35 engine with snorkel air cleaner assembly. All 396

cid engines came with flash chromed rocker arm covers, a flash chromed

air cleaner assembly lid, and this instance on an L35 engine with positive

ventilation, a flash chrome oil breather All 1967 Chevelle 396 engines

have this 'dent' on the rear of the drivers side rocker arm cover for

power brake clearance whether power brakes were ordered or not.

When optioned with Closed Engine Positive Ventilation System (RPO K24)

the oil breather cap was replaced with a hose assembly to route crankcase

fumes from the cylinder head to the bottom of the air cleaner assembly

to help reduce emissions.

When equipped with GM's Air Injection Reactor emission system (RPO K19),

the oil breather was replaced with a hose running from the oil breather

location to the base of the air cleaner assembly and is referred to

as a 'closed positive ventilation' system. Crankcase vapors that would

normally have escaped into the air from the oil breather cap are now

directed back into the airflow to the carburetor.

The 350-hp

(RPO L34) engine came with the same flash chrome rocker arm

covers but sported an open element air cleaner assembly with a flash

chrome lid. All 350-hp

engines were equipped with a closed positive

ventilation system - note the hose running from the rocker arm cover

to the base of air cleaner assembly.

This 350-hp

engine is outfitted with GM's Air Injection Reactor emission

system (RPO K19).

The special high performance 375-hp

(RPO L78) engine featured a solid

lifter camshaft, bigger rectangular port heads, an aluminum intake manifold,

and bigger Holley carburetor. Note the deep groove pulley on the alternator

to help retain the alternator belt at high RPMS.

The carburetor return spring was now attached to lower portion of

the carburetor throttle linkage and the ignition coil bracket, not

to the upper alternator brace as it was in 1966. See

1966 Engines page.

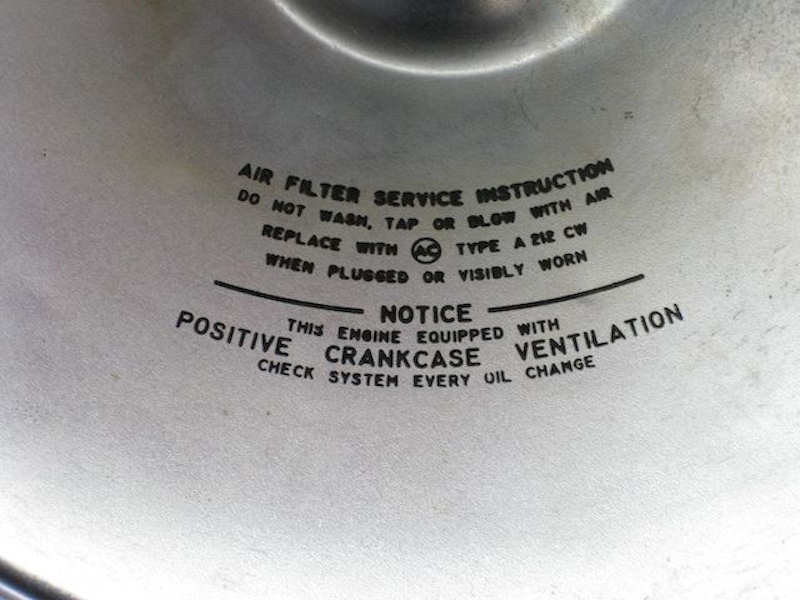

The underside of the open element air cleaner assembly lid with service

information.

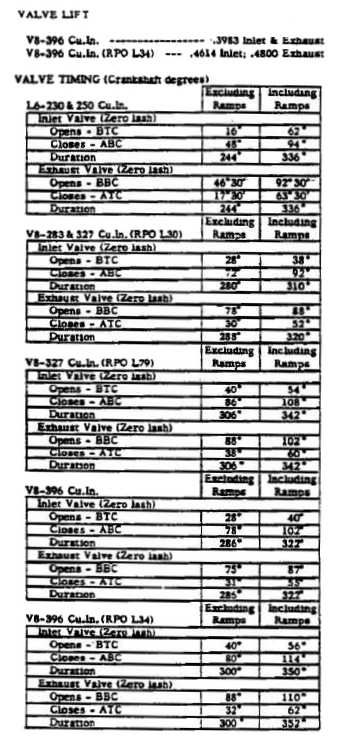

Camshaft Specifications

Note the oil groove in rear cam journal of this 396 V8 camshaft on

the left. Both 1965 and 1966 396 V8 engines require this groove

along with corresponding rear cam bearing. Most aftermarket camshaft

manufacturers DO NOT list the 65/66 396 V8 in their catalogs due to

this groove. However, any later camshaft will work if grooved and

most aftermarket cam suppliers will either groove the cam for a

nominal fee or send you the specifications so you can have your

local machine shop perform the operation