C4 CorvetteWorld

Reverse Flow Cooling

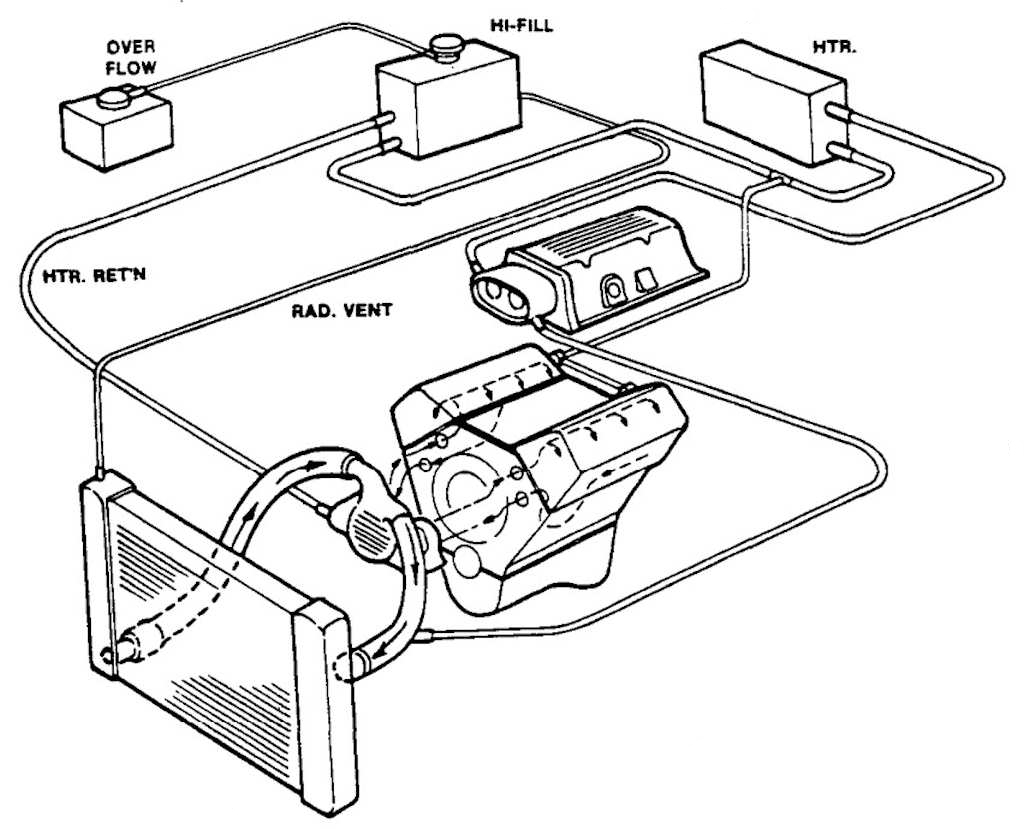

Unlike conventional cooling systems that send cold coolant directly from the water pump through the engine block and then the cylinder heads, reverse flow technology routes the coolant to the cylinder heads first. After the cylinder heads are sufficiently cooled, the vapors (if any) are vented off, and the coolant circulates through the engine block.

The coolant pump is the heart of the cooling system. Its cast internal passages route coolant through the engine without sending it through the intake manifold, eliminating potential leaks. The gear-driven pump ensures coolant flow even if the accessory drive belt fails. The gear drive eliminates side-load stresses on the pump bearing, improving its reliability.

Benefits of the reverse flow cooling include an overall reduction in the amount of pressure in the system and the elimination of pitting or cavitation erosion of the pump and seal. Heat transfers in the engine and radiator is more efficient. Routing the coolant to the cylinder heads first contributes to higher bore temperatures and reduced ring bore friction, and assures adequate cooling around the valve seats and spark plug bosses. Strategically located bleed valves allow an air-free system during service, eliminating the need for multiple thermal cycling.